Ixthus Instrumentation returns to RAILTEX with a comprehensive selection of measurement solutions for the rail industry from its distribution partner RIFTEK – the developer and manufacturer of specialised optoelectronic instruments. Visitors to stand L86 can discuss applications with Ixthus engineers and view a wide range instruments for maintenance and inspection tasks such as wheel diameter and wheel profile, disk brake profile and back to back wheel distance measurement. Aimed at portability as well as for test bench and development laboratory use, RIFTEK’s instruments feature a choice of display only and/or wireless data transmission plus comprehensive data logging software for high precision geometrical measurement.

Visitors are also be warmly welcomed to discuss specialised systems developed by RIFTEK for applications such as real-time wheel geometry measurement and dynamic position control of power rail position that have also been developed by the specialist.

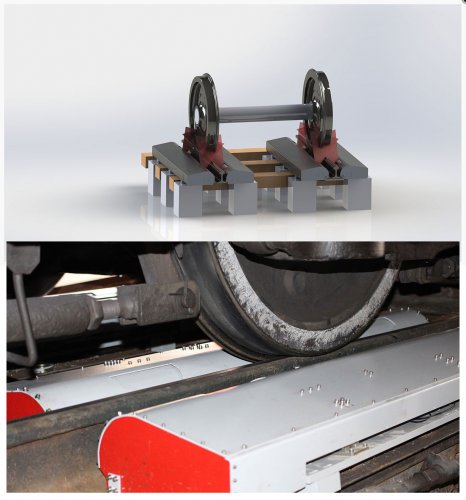

Image: RIFTEK IKP series wheel profile gauge – available from Ixthus Instrumentation

RIFTEK’s IKP-5 series laser equipped wheel profile gauges are available in various sizes to suit standard wheels or as short and super-short versions for tramway wheels. These Bluetooth® enabled gauges include software and an operator PDA with a user-friendly interface. Flexible setting of measured and calculated wheel flange parameters include flange height, thickness and slope, wear parameters, angular profile parameters and much more. All data can be synched to external storage or PC for wheel sets wear data processing and analysis.

For exacting rail profile measurement, the PRP series covers the cross-section geometry of the working railhead surface with full profile scanning and analysis of the railhead acting face plus graphical image visualisation of the combined actual and ‘as new’ cross sections. With Bluetooth wireless transmission to PDA and PC interfacing, the PRP series can perform analysis that conforms to the EN 153092 Standard.

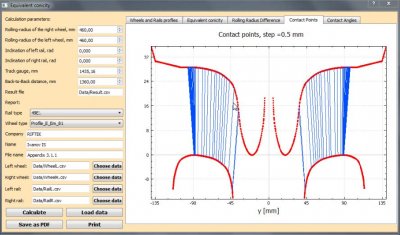

The IKP and PRP series gauges can combine with RIFTEK’s ‘Equivalent Conicity Calculation’ program to determine the dynamic interaction between railway vehicle and track. The program calculates contact point position and rolling radius difference depending on displacement of wheel set, as well as contact angles and their difference depending on displacement of wheel set.

Image: Screen shot from RIFTEK’s Equivalent Conicity Calculation’ software

IDK & IDK-BT series gauges are designed for straightforward rolling circle wheel diameter measurement using the ‘three points’ technique. Without the need for costly wheel set roll-out and no need for complete wheel coverage, the IDK version includes a numeric display to show the wheel diameter whilst the IDK-BT gauge features a Bluetooth interface for transfer of results into the supplied wheel-set wear database management system.

RIFTEK’s range of back-to-back wheel distance measurement gauges for railway, metro and tram wheels will be on show. For check-up, examination, repair and formation of wheel sets, measurements are made directly on rolling stock without wheel set roll-out. Visitors can also see RIFTEK’s IKD series laser-based scanning devices for brake wear and profile gauges. These handheld instruments include a database and software package for complete evaluation and storage of disk wear data.

A 12-page brochure ‘Measurement Instruments for Railway Transport’ and further information on the RIFTEK range is available from Ixthus Instrumentation at :

www.ixthus.co.uk

or call +44 (0) 1327 353437 or email [email protected] for details.