Croft Filters Ltd, based in Warrington England, have been supplying custom filtration and separation solutions for over 32 years. Throughout this time Croft has developed a reputation for their quality, bespoke service through manufacturing a variety of products for specific requirements. These products have included: Filtration Cones, Baskets and Screens, Disc Filters and Filtration housings amongst others and are made with Wire Mesh, Wedge Wire and Perforated Plate, depending on the product’s design. Croft continues to supply a wide range of industries including Oil, Gas, Pharmaceutical Food and Beverage. As a result of this and due to the application requirements, most of Croft’s products are manufactured using Stainless Steel 316L.

Croft continues to meet Customer’s demands by heavily investing into research and development of their custom filtration solutions. In 2013 Croft invested into Additive Manufacturing, specifically Selective Laser Melting (SLM) in order to develop new innovative filtration solutions.

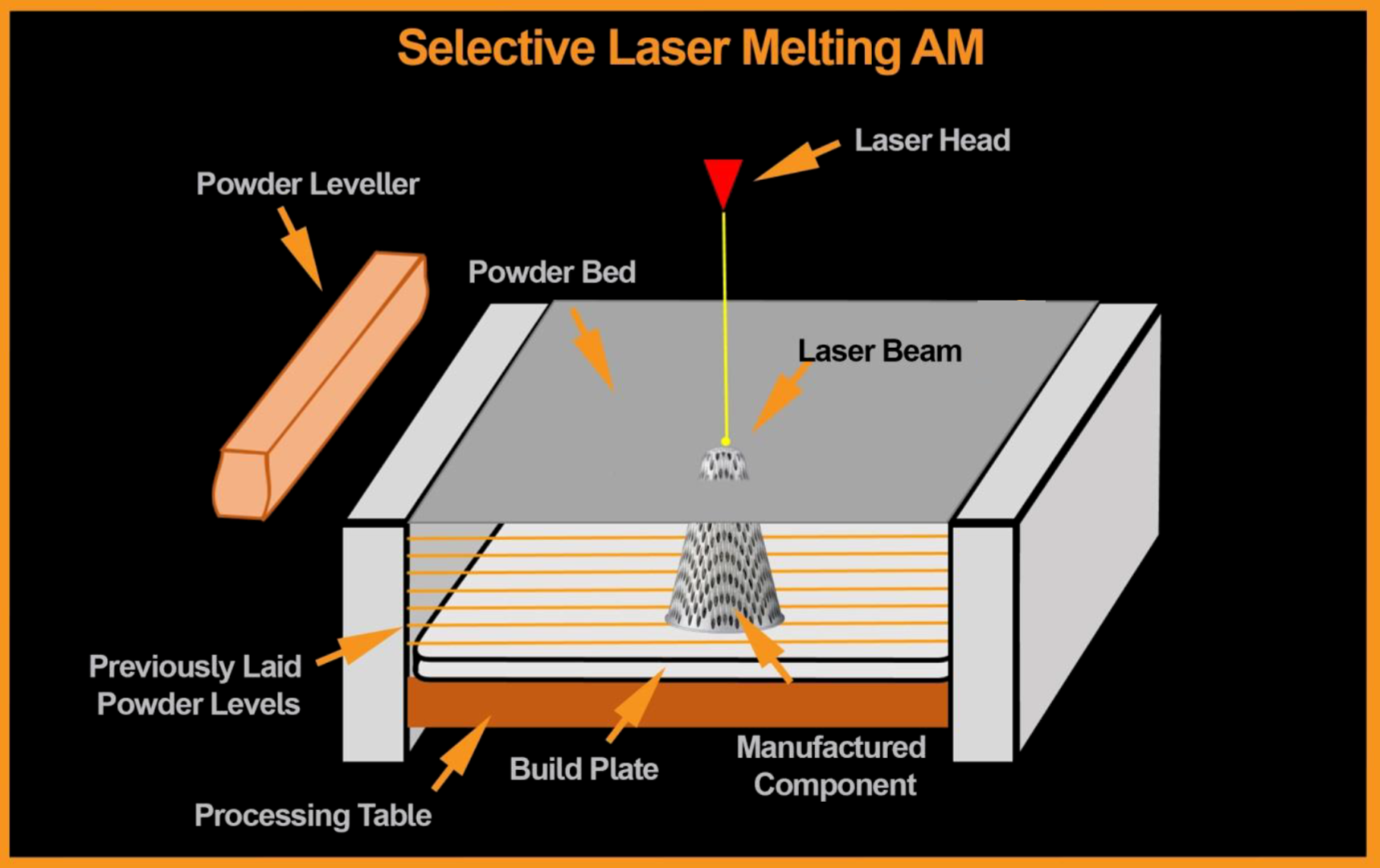

Additive Manufacturing (AM), also known as metal 3D printing, is the process of creating a 3D component in a series of layers. The process uses a metal powder, in Croft’s case this is Stainless Steel 316L. The powder is spread evenly across a buildplate as a laser then melts the powder according to a CAD file. The build plate then drops between 50 micron and another powder layer is added. The laser then melts this layer to the previous. The process is repeated until the final part is complete.

This process differs to subtractive methods, only using the required material to build the part as any excess powder that has not been fused is recycled back into the machine’s powder delivery system.

Benefits of the Additive process, such as: part weight reduction, multi-part to single component and expanded design capabilities, allow Croft’s customers to re-think their approach to their designs in order to improve the efficiency, utility or aesthetics of their parts.

Each component has been designed to give supply-chain advantages whether that is to reduce lead time by manufacturing multi-part components as a singular part (eg Wedge Wire) or whether the component itself is more efficient such as Croft’s ‘Straightliner Filter™’.

Quality of both product and service has been the key to Croft’s success; the Company takes great pride in understanding customer’s needs, quickly supplying them with a high quality product that exceeds Customer’s expectations.

For more information:

Visit: www.filters.co.uk

Call: 01925 766265