Anti-food-waste expert, WRAP, declares that around a third of all food produced is lost or wasted, contributing 8 to 10 percent of overall man-made greenhouse gasses.[1] Food Waste Action Week 2022 (7th –13th March) aims to help slice global food waste in half by 2030.[2] After celebrating the success of its first event in 2021, this year’s sustainability pact will be the tipping point for actionable change.

It is clear from the WRAP 2021 report that food processors are already successfully implementing waste interventions. There has been an astonishing 45 percent increase in UK redistribution in 2020 with the help of WRAP’s Food Waste Action Week 2021, equating to over 92,000 tonnes worth £280 million,[3] and considering the climbing food costs, these savings are immense.

Even so, the UN Sustainable Development Goal (SDG) strives to reduce food waste by 50 percent in the next decade. If businesses are to meet the new Courtauld Commitment environmental targets for 2030, there is still some work to be done.

Food safety and inspection champion, Fortress Technology, examines the changing attitudes towards food waste and how automation and lean manufacturing can bring a greater sense of transparency and greener thinking to the food chain.

- Lead with efficient automation

By leading with efficient automation, it is far more likely that food processors, equipment choices and quality control processes will facilitate the reduction in food waste manufacturing, rather than hinder it. The utilisation of automation tools and ‘smart’ inspection machinery will help to ensure waste, safety and production efficiency remains tightly controlled.

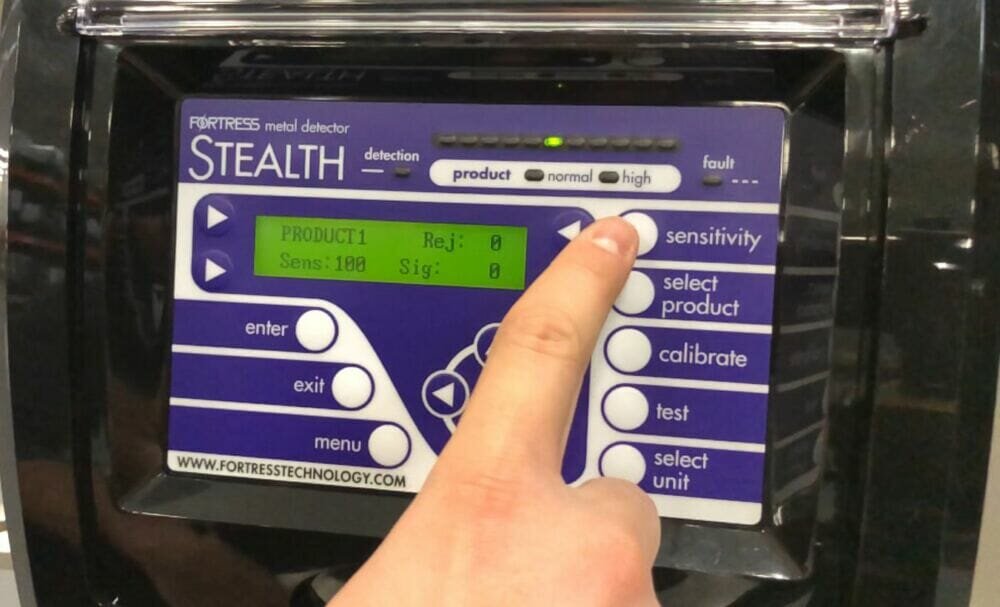

Fortress Technology’s Managing Director Phil Brown expands: “Most of today’s food metal detectors are ‘smart’ and connected. This allows immediate and remote access, enabling food manufacturers to view the current equipment status, monitor rejects and maintain continuous, smooth production lines.”

2. Tighten time-saving procedures

Manually carrying out regular checks can drain resources; consider implementing digital testing instead. Guaranteed to save food manufacturers time and money, Halo Digital Testing from Fortress automatically and independently checks for all metal materials – ferrous, non-ferrous and stainless steel.

The unique new conveyor design, featured on the company’s premium Raptor checkweighing series, is another big labour, time and money saver. Overcoming the challenge of loosening belt tension during machine sanitation, operators simply unclip and disconnect the conveyor motor, lift out and re-assemble in seconds.

The new Raptor checkweighing series can pinpoint upstream operational deficiencies, including overfilling of packs, processing and packaging waste

Utilising automation tools and ‘smart’ inspection machinery helps to ensure waste, safety and production efficiency remains tightly controlled.

3. Optimise detection

High-speed, multi-line food packing operations can produce huge amounts of unnecessary waste. The rejection systems can remove an entire line of produce across all lanes being checked, resulting in tonnes of quality product gone to waste. These losses not only impact environmental waste but economical too, as it is estimated the cost per line of false rejects is at over £14,000, depending on the scale of the problem.

Given that food processors use a wide array of mixers, dicers and slicers – most made from stainless steel – Fortress has intentionally focused its efforts on addressing harmful contaminant risks and reducing by-product. Upstream inspection machines can help to capture contaminants in their largest form, minimise waste and enhance productivity.

Phil explains: “Upstream is often the place where we can get two or three times the performance level. There is a better opportunity to identify where the source of a potential problem may be if there are several units throughout the line, especially when adding ingredients at different points or performing different processes.”

4. Stop the surplus production

Overproduction and overfilling dramatically contribute to annual food waste numbers. Even a few grams surplus in every food pack can rapidly equate to thousands of pounds per month; inefficiencies that the Fortress Raptor checkweighing and combination series targets.

By capturing sample readings by the millisecond, the high-end Raptor control system provides accurate and consistent weighing results which is a game changer for food factories concerned about product waste and giveaway, explains Phil. “Using Raptor’s digital data capture feature, manufacturers can pinpoint upstream operational deficiencies, including overfilling of packs, processing and packaging waste.”

5. Remember waste always has a value

Whether it is environmental, economic or productivity-measured, food waste always has a value. By investing in accurate weighing, dosing and inspection equipment, manufacturers can add back into their bottom line to strategise future production methods and combat rising food costs.

The increases in energy costs, CO2, transportation and labour make it even more imperative to consider the whole waste picture and how precision processing can protect profit margins too. Implementing time-saving and digital processes, automated calibration of machinery and better detection systems can all help to acquire financial savings and tackle this war on food waste.

[1] WRAP, ‘Food Waste Action Week 2022,’ URL: here.

[2] Ibid.

[3] WRAP, ‘WRAP Courtauld Commitment Annual Report 2021,’ URL: here.ourtauld-Commitment-Annual-Report-2021.pdf