(Arvada, CO, USA 18th January 2021) Leading nanometer-level motion control solutions innovator ALIO Industries, is heading an initiative to ensure that manufacturers seeking highly accurate motion control solutions do not end up investing in sub-optimal solutions — either due to a lack of understanding of the differences in available technologies, or by partnering with suppliers that do not have the pedigree to achieve the precision required.

Questions need to be asked that delve into motion control vendors’ capabilities and their values. Only by so doing will manufacturers avoid the wasted time and expense as they strive for greater and greater precision.

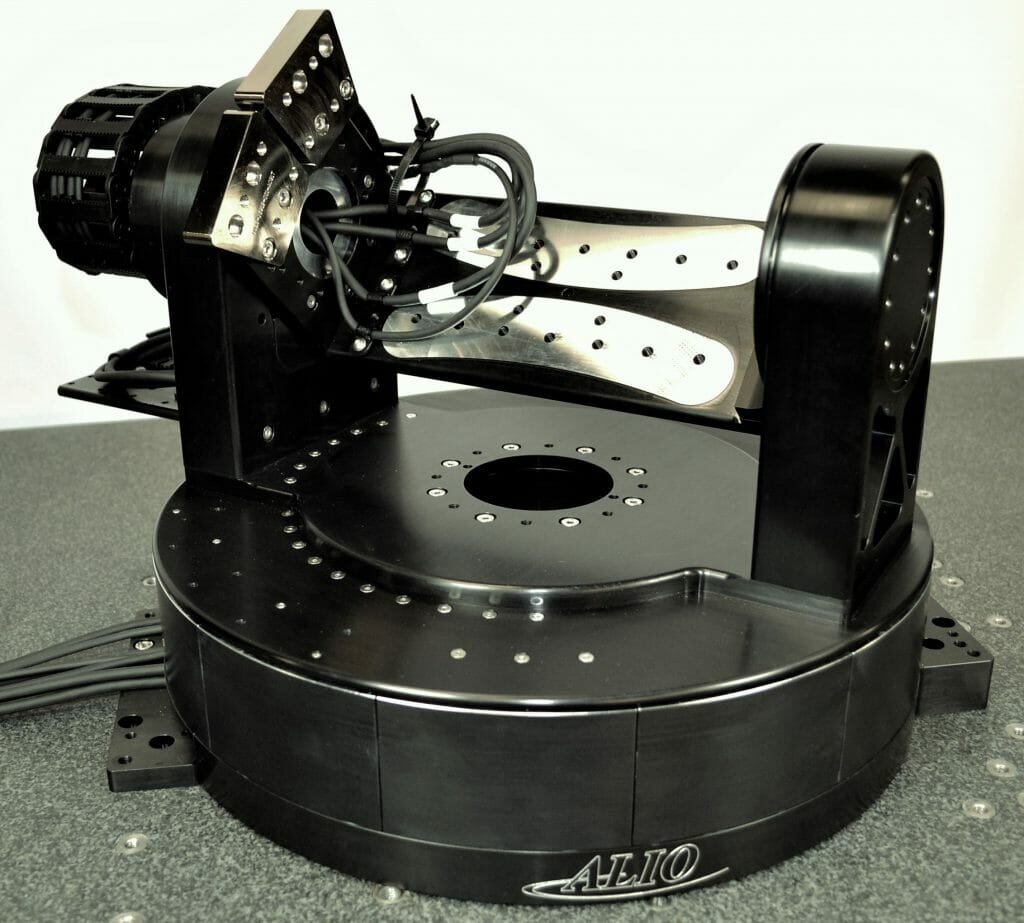

Bill Hennessey, CEO at ALIO says, “If your short-listed precision motion control technology provider is really credible, it will be able to show you a series of innovative solutions that redefine the motion control market. Here you should be looking for evidence of next-generation technologies, not variations of legacy traditional motion control technologies. This is like the difference between vendors selling hexapods and a company like ALIO Industries that sells the Hybrid Hexapod®, which overcomes process limitations in traditional hexapods, and exhibits orders-of-magnitude improvements in precision, path performance, speed, stiffness, and larger work envelope.”

“Pinning down motion control vendors over statements of precision is a minefield. Ultimately, claims on nanometer-level precision are meaningless unless this nanometer-level precision is achieved repeatably. Vendors that cannot achieve repeatable nanometer-level motion control often need to resort to at worst false, and at best illusory claims. So saying look for evidence of vendors that are trying to move the conversation along. ALIO Industries, for example, now talks in terms of Point Precision® referencing performance specifications to a point in space at the single digit micron or nanometer level. It is vital that you interrogate precision claims diligently before a making motion control technology purchase. It is also critical that ASTM and/or other internationally registered standards are followed by vendors, instead of methods developed to place a particular vendor’s products in a better light, and which provide flattering data calculations which give a false illusion of precision,” Hennessey continues.

Most vendors sell off-the-shelf solutions and leave their customers to align them with their specific applications. In a way, this demotes motion control to a necessary evil, a link in a process chain that is expensive and complicated. But when a vendor provides truly cutting edge nanometer-level accurate and repeatable motion control solutions, it elevates motion control from a necessary evil to an enabling technology. If a vendor provides the best-in-class, most accurate, and most repeatable motion control solutions on the market, they will be able to push the boundaries of what customers may see as possible, and will therefore promote the ability to innovate. Try and assess a short-listed vendor’s view of motion control. Do they see obstacles and problems, or opportunities and solutions?

Walter Silvesky, VP Sales at ALIO says, “Ideally your chosen motion control technology vendor should not sell products but instead solutions. The key is to be able to customize motion control solutions to specific customer applications. A vendor supplying nanometer-level motion control solutions should be able to prove its credentials and demonstrate that it has provided a significant number of best-in-class, efficient, and cost-effective motion control solutions for an array of different industry applications. Ask your chosen vendor for evidence!”

Beyond technological pre-eminence, a motion control technology provider should place an emphasis on being a strategic partner in product development. It is only by doing this that customers can be confident about achieving challenging motion control and manufacturing goals.

Vertical integration is another key to success. When working in a world where nanometer-levels of accuracy are the norm, it is vital that motion control products are manufactured in one facility. Ask a vendor whether they have design, machining, metrology, manufacturing, and assembly under one roof. The cross collaboration between product development teams is vital to the achievement of reliable and repeatable ultra-precise motion control solutions.

Silvesky concludes, “Also, drill into the experience and technical know-how of your short-listed vendor’s team. Especially when a customer’s demand is for nanometer-level motion control, it is important to make sure that a vendor has a dedicated focus which will translate into innovative and cutting-edge motion control solutions. Much of this is about the culture in a vendor company. Assess whether you detect a “can do” attitude and whether your vendor seems to nurture a collaborative environment. In essence the choice of a nanometer-level motion control solutions provider is based on a number of factors, and is a mix of not just technological competencies but also core values and what “makes a company tick”. Investment in an ultra-precise motion control solution is expensive, and customers need to be certain before nominating a motion control vendor that they will have a best-fit solution that is right first time.”