Analytik reports on pioneering work undertaken by Professor Welland’s group at the Nanoscience Centre in the Department of Engineering at the University of Cambridge (UK) using a LM20 Microfluidizer to help produce high conductivity carbon nanotube films.

Carbon nanotubes are amazing conductive materials that are very strong, flexible, and chemically stable. Their large-scale industrial adoption has been hampered due to the unavailability of an industrially compatible process to produce very high conductivity carbon nanotube dispersions, which does not require toxic/hazardous materials like acid and strong solvents.

Dr Atif Aziz of the University of Cambridge commented “Our recent developmental work has resulted in a very scalable process that produces carbon nanotube films with high thermal conductivity and lowest sheet resistance. Most importantly, we achieved this without using hazardous materials, and our method involves only a one-step dispersion process. The solvent and dispersion agents used in our process are water and cellulose respectively, which are not only non-hazardous but also abundant in nature. The process we developed uses a LM20 Microfluidizer, supplied by Analytik Ltd, that can be scaled up to produce carbon nanotube dispersions of hundreds of litres per day. Simplicity and scalability make this process very attractive for industrial adoption”.

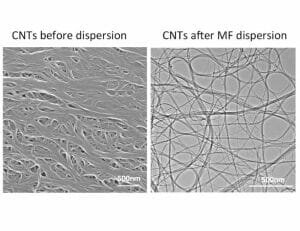

Dr Aziz added ” The most important advantage of using a LM20 Microfluidizer is that all the Carbon nanotubes present in the solution experience the same shear force during dispersion, which is not possible to achieve by using conventional sonication methods. My team has been very pleased with the excellent technical support provided by Analytik, which has enabled us to fully exploit the extensive capabilities of the LM20 Microfluidizer for the production of our novel high conductivity carbon nanotube films.”

The LM20 Microfluidizer represents the gold standard for producing uniform nano emulsions and particle size reduction. The system is a digitally controlled high-pressure homogeniser that maintains identical sample processing conditions, enabling it to reliably produce desired results, including uniform particle and droplet size reduction. The LM20 Microfluidizer is widely proven to linearly scale up from lab to pilot and production volumes.

For further more detailed information on the LM20 Microfluidizer please visit https://analytik.co.uk/product/cell-disruption-lm20-microfluidizer/ or contact Analytik on +44-1954-232776 / [email protected].

For a copy of the recently published paper ‘Double-Walled Carbon Nanotubes Ink for High-Conductivity Flexible Electrodes’ describing the pioneering work of Dr Aziz and colleagues please visit https://pubs.acs.org/doi/10.1021/acsanm.0c02013?ref=pdf. This work was funded by Lloyds Register Foundation, London, UK.

For over 15 years – Analytik has been a trusted supplier of cutting-edge scientific instrumentation to leading organisations throughout the UK and Ireland. Specialists in providing and supporting pioneering technology,, we deliver added value through specialised consultative expertise and comprehensive pre and post-sales support to ensure that our customers get the most out of their investment. For further information please visit www.analytik.co.uk.