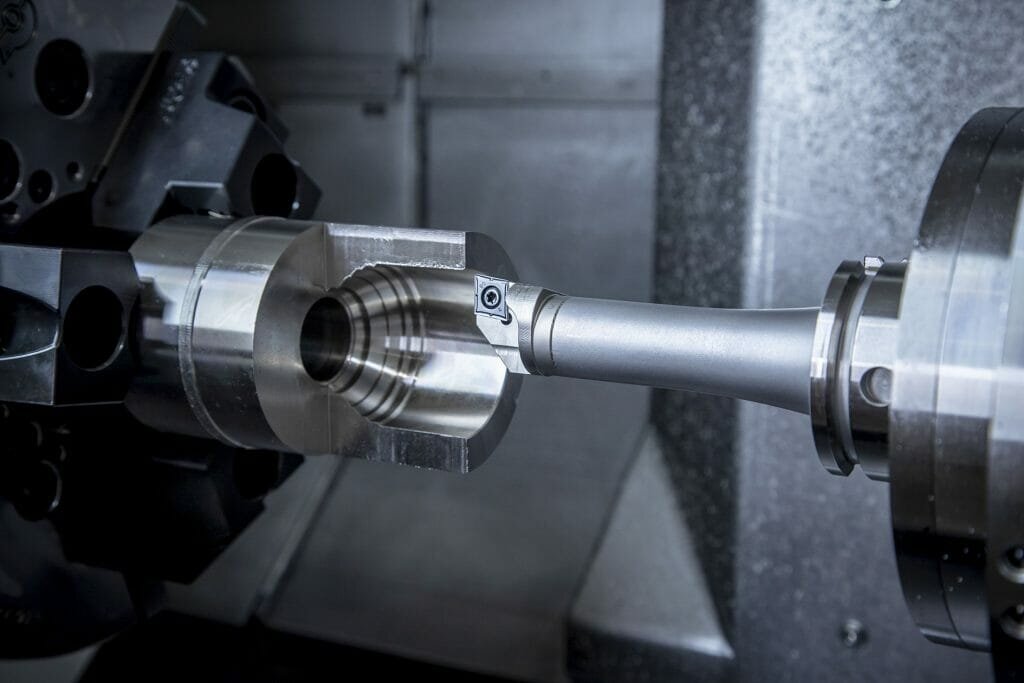

Quality and efficiency of the machining process can be measured in using a wide range of parameters amongst which are surface quality and process security. The new vibration-damped boring bars from Team Cutting Tools at the CERATIZIT Group will reliably reduce vibrations and, together with the flexibility of the brand-new exchangeable head system, guarantee top quality surface finish.

Uncontrolled vibrations often result in the scrapping of an expensive workpiece, leading to reduced profit and efficiency. However, long tool overhangs are often essential so what is the answer? CERATIZIT has provided the solution with the combination of its new vibration-damped boring bars and flexible exchangeable head system. Prior to this development, machine operators approach to reducing vibrations was to reduce cutting data, such as cutting depth, cutting speed or feed. “With regards to the highest possible efficiency, this is only a temporary workaround as the cycle time often decides whether an order is profitable or not. The CERATIZIT solution is a newly developed exchangeable head system, which can be used with base holders, but also with special boring bars. These minimise vibrations thanks to the damping system in the tool body,” explains Christoph Retter, Product Manager at Team Cutting Tools.

As a result of the design of the CERATIZIT system users are finding that instead of reducing the cutting data, they are able to use even higher feeds and speeds. This leads to reduced cycle times where long tool overhangs are involved, while also generating improved surface finish. Tool life is also improved along with significant benefits to the machine itself, with elements such as spindles under less strain. “This provides for greater sustainability, as all of the components used last significantly longer. Together with the cost savings achieved from extended tool life, the machine operator can now complete even tricky tasks with an increased sense of calm,” says Christoph Retter. Thanks to vibration damping, applications are possible that would not be under normal conditions with minimum cutting parameters.

Key to optimised machining with the vibration-damped boring bars is the newly developed modular exchangeable head system from CERATIZIT. With a choice of eight different exchangeable heads, the system is extremely variable, flexible and versatile, resulting in reduced consumable costs for the user. These heads also feature clever positioning of the coolant nozzle, ensuring highly efficient cooling and improved chip clearance.

Standard versions of the base holders are available from CERATIZIT in 200, 218 and 283 mm lengths and diameters of 25, 32 and 40 mm, with the vibration-damped versions available in 150, 185 and 225 mm lengths. Their strengths include process security, reduced costs per component, optimum chip clearance and improved surfaces – and the full benefits can be seen irrespective of the materials to be machined. “These vibration-damped boring bars will bring a sense of peace and calm during machining for both the tool and user,” says Christoph Retter.

To coincide with the arrival of the latest Up2Date supplementary catalogue from CERATIZIT the vibration-damped boring bars and modular exchangeable head system are now available from stock.

More information can be found at https://cuttingtools.ceratizit.com/gb/en/machining-know-how/turning/product-overview/boring-bar.html

The basis for optimised machining with the vibration-damped boring bars is the newly developed modular exchangeable head system from CERATIZIT. It includes eight different exchangeable heads.