Market developments and customer enquiries make it clear that the trend towards holistic solutions using combination batches is constantly increasing. Color masterbatches combined with additives can not only fulfil color specifications but can also individually guarantee additional technical requirements for the finished part. Process optimisation and the resulting cost and time savings can be additional advantages.

By bundling market observations, customer requirements and own expert knowledge, the masterbatch manufacturer AF-COLOR, branch of AKRO-PLASTIC GmbH, presents under the brand AF-COLOR Selection products from different specialist areas.

Masterbatches for optimised laser marking (AF-Color® *LA)

In selected applications, the use of laser-sensitive additives in plastics is a clear advantage. They can increase both contour sharpness and contrast.

These properties are extremely valuable in laser marking, for example in machine-readable codes, especially in the context of quality assurance and traceability. In addition, the resulting improved process speed is a considerable added value. A laser marking that is clearly visible to a reader or even the naked eye speeds up further processing considerably.

The laser additives of AF-COLOR originate from the AF-Complex® product line and are available as pure additive concentrate or in combination with color.

For transparent and semi-transparent materials, additives cause a more even contrast distribution, which also leads to the above mentioned advantages.

The additives are therefore multifunctional in the field of laser application. In addition to the technical component, color design also plays a major role. With the combination masterbatches (color + additive) you get maximum flexibility in the color composition.

” Whether dark, light or colored markings. Any combination can be created with an individually produced color formulation”, explains Dirk Schöning, Sales Director at AF-COLOR.

Masterbatches for improved laser transparency (AF-Color® *LT)

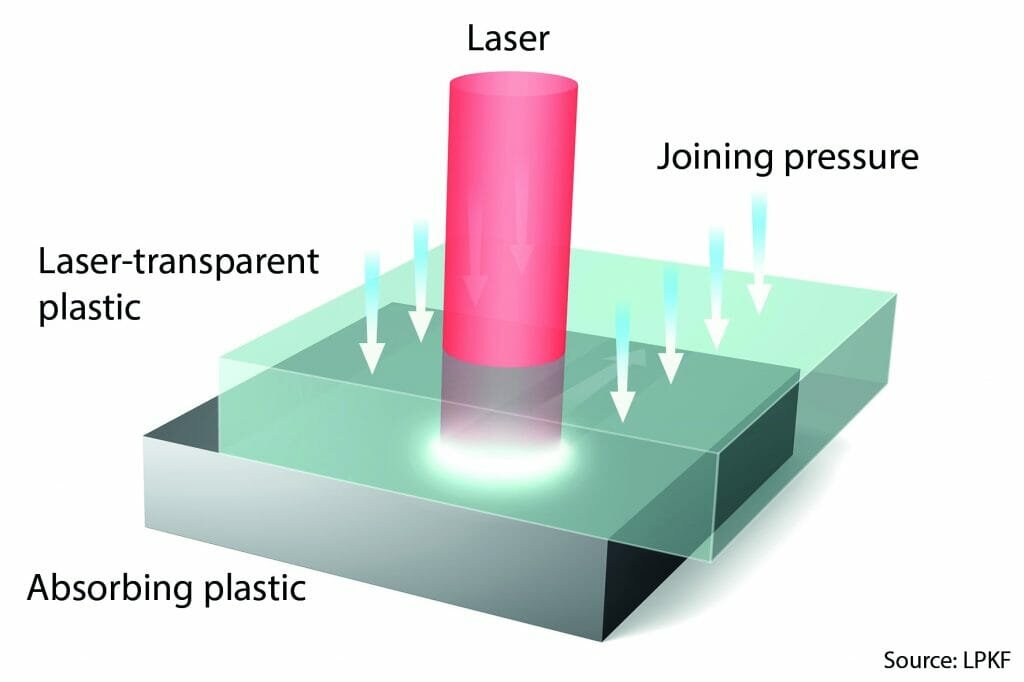

Laser welding is a non-contact welding process which is used for very narrow tolerances of the components to be joined. Two types of thermoplastic materials are joined together in this process: The transparent joining partner is irradiated by the laser, the absorbing one is heated. The absorbing plastic melts the transparent joining area and is pressed together with a suitable device. Application examples can be found in medical technology, automotive, electronics or even household appliances.

One of the key factors for a high-quality welded joint is the coloring of the components. Any contamination by particles, e.g., in the form of pigments, interferes with the process. An optimal basis for laser transmission welding can be created by a suitable choice of polymer and alternative colorant.

“Together with our parent company AKRO-PLASTIC, we have a long experience in the production of these laser transparent and also polyamide-based masterbatch formulations”, says Schöning.

Schematic sketch laser welding (Source LKPF Laser & Elektronics AG)