DOT® Fasteners were one of the first products offered by JET PRESS when they opened in 1977. Durable™ Snap Fasteners, Pull the DOT® Fasteners and Common Sense® Turn Button Fasteners are still popular items. DOT® Fasteners play a role in in our lives in many ways. They are used for seats in modern cars and soft tops in classic cars. Boats of all sizes use DOT® Fasteners and they feature on clothing like motorcycle wear and military kit.

Because JET PRESS sell DOT® Fasteners to classic car restorers, they know they’ve been used by car designers for many years. But they dug a little deeper and found fasteners similar to modern DOT® fasteners in some surprising places throughout history.

Because JET PRESS sell DOT® Fasteners to classic car restorers, they know they’ve been used by car designers for many years. But they dug a little deeper and found fasteners similar to modern DOT® fasteners in some surprising places throughout history.

The first lift the dot fasteners

As far as JET PRESS can establish, lift the dot fasteners were first used to hold curtains back on horse drawn carriages. The military saw how strong and versatile these fasteners were and used them for satchel bags and gun holsters – where they are still used today. The marine industry adopted them as well and JET PRESS still sell many DOT® Fasteners to boat builders and chandlers.

Cars and planes

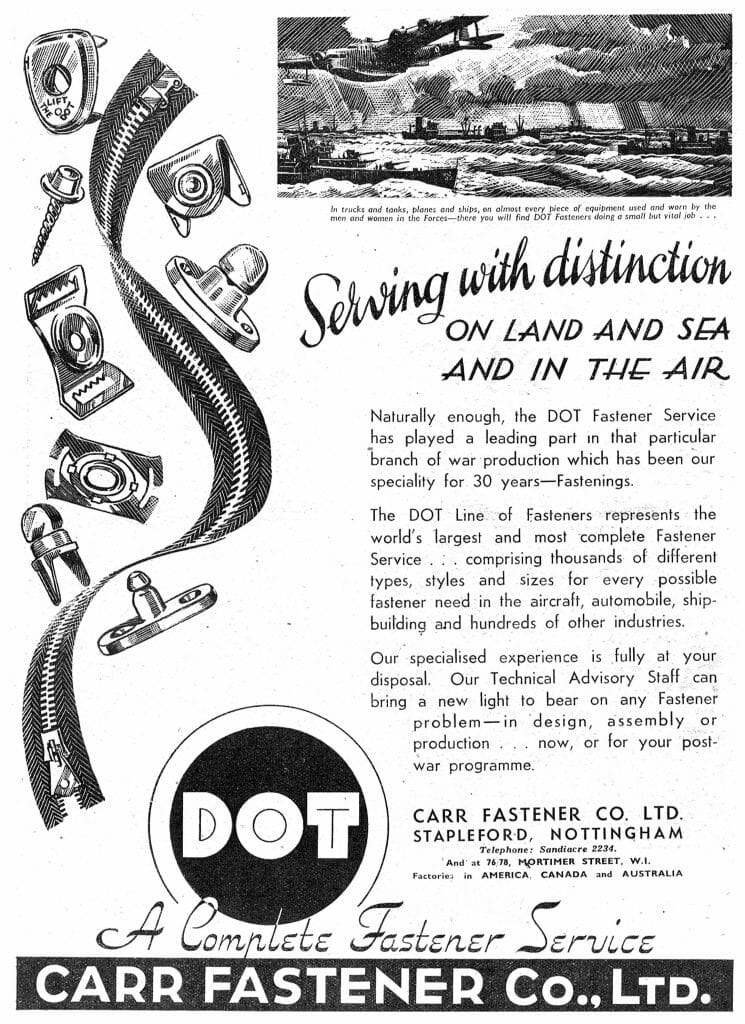

Over a hundred years ago the people who were building cars and aircraft made good use of DOT® Fasteners. By the time of the Second World War DOT® Fasteners were an integral part of many aircraft.

JET PRESS found ads on the Database of British Aviation Advertisements featuring DOT® Fasteners. The Blackburn Skua featured in the first advert was used by the Fleet Air Arm. It was the first monoplane to fly from the Royal Navy’s aircraft carriers and sank the German cruiser Konigsberg in Norway early in the war.

Then into space

On July 21, 1969 Neil Armstrong was the first man to set foot on the moon. The spacesuit he wore incorporated DOT® Fasteners. This was the A7L suit made by ILC Dover a division of Playtex, better known for making bras. The A7L suit is a later version of the A5L which won a competition run by NASA to find the best pressure suit for the astronauts in the Apollo programme.

And back to earth

To the best of their knowledge, all the DOT® Fasteners JET PRESS sell stay on planet earth. They are generally used to attach fabrics, including leather, to other fabrics or other materials.

Common Sense® Turn Button Fasteners are designed so they don’t open accidentally. They have a spring mechanism holding the fastener in place until you give it a quarter turn. They come with various fixing options for different surfaces.

Common Sense® Turn Button Fasteners are designed so they don’t open accidentally. They have a spring mechanism holding the fastener in place until you give it a quarter turn. They come with various fixing options for different surfaces.

Durable™ DOT® Snap Fasteners are self-piercing and offer a firm hold. You will be familiar with the firm snap when you use them on clothing, tents, luggage and many other everyday items. They come in a range of sizes with different fixings.

Lift-the-DOT® Directional Fasteners can only be released when lifted in the correct direction. This makes them very useful in a range of applications like holsters so they can’t easily be undone by accident. They also have a far greater shear strength than press studs.

In most cases it’s best to use specialist tools for attaching DOT® Fasteners. JET PRESS can supply a Hand Tool Bed & Punch for use on a bench. The M840 Snapmaster is handheld so it’s useful for repairs and working in restricted spaces. When you want to attach large volumes of DOT® Fasteners, JET PRESS can supply a Manual Foot Press. You can expect to attach 400-900 parts per hour using this tool.

DOT® Fasteners have certainly played their part in history and JET PRESS are confident they also have a role in the future.