Printed/flexible electronics, already used in smartphones and sensors, are forecast to be widely adopted in applications ranging from medical devices to smart packaging. This technological transition provides extensive opportunities for innovative materials, including amongst others novel OLED emitters, conductive inks, and conductive adhesives.

Innovative functional materials are obviously a fundamental part of the value chain for any emerging technology, but this is especially true of printed/flexible electronics since materials need to combine electronic/semiconducting functionality with being flexible and/or solution processable as well as being stable and straightforward to manufacture. IDTechEx’s new report, “Materials for Printed/Flexible Electronics 2021-2031: Technologies, Applications and Market Forecasts”, covers a wide range of materials for printed and flexible electronics, spanning multiple applications:

- Materials for organic light emitting diodes (OLEDs).

- Materials for organic photovoltaics (OPVs).

- Materials for organic photodetectors (OPDs).

- Materials for organic thin film transistors (OTFTs).

- Carbon nanotubes (CNTs).

- Semiconducting perovskites.

- Quantum dots.

- Functional inorganic inks.

- Component attachment materials, including isotropic/anisotropic conductive adhesives and low temperature solder.

- Conductive inks, including stretchable/thermoformable, nanoparticle-based, particle-free and copper inks.

In total, IDTechEx Research forecast that the market for specialized solution processable materials for printed/flexible electronics will reach $6.9Bn by 2031. This new report provides a comprehensive overview of all solution processable materials that are compatible with printed/flexible electronics, with an emphasis on the most interesting emerging technologies. The report identifies the dominant technical and market narratives across the printed/flexible electronics materials space, provides SWOT analysis for each material class and profiled company, and both assess technological and commercial readiness. IDTechEx forecast organic semiconductors (primarily for OLEDs) and component attachment materials to be the largest materials markets in printed/flexible electronics by 2031.

Innovation opportunities

Organic semiconductors are very well suited to printed/flexible electronics given their tunability and compatibility with solution processing. Clearly OLEDs are the big commercial success story, with the displays now a $30 bn market. However, there are still extensive opportunities for innovative organic semiconductors across multiple applications.

Within OLEDs, notable trends are the transition to thermally activated delayed fluorescence (TADF) emissive materials, and novel host materials that promise reduced emissive species aggregation and thus enable greater efficiency. There is also renewed interest in organic photovoltaics (OPV), with the recent transition to non-fullerene acceptors improving both efficiency and stability. OPV is especially well suited to applications such as building integrated and indoor photovoltaics.

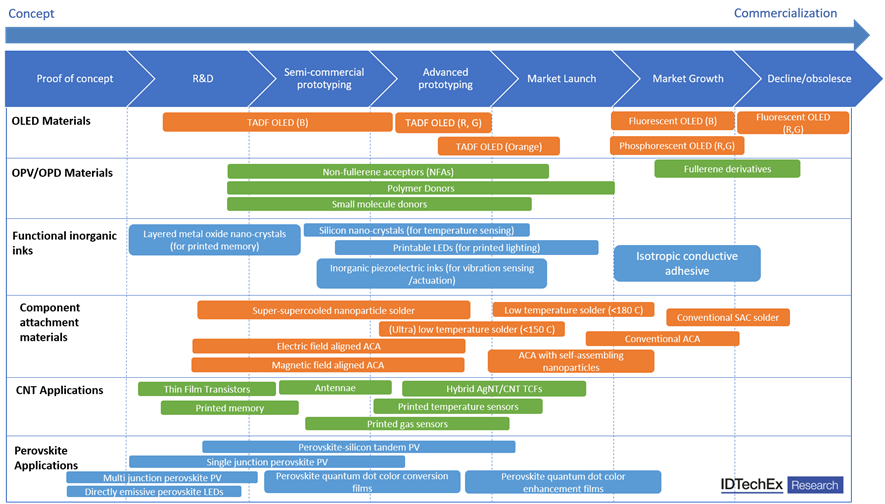

Furthermore, organic photodetectors (OPDs), which employ very similar materials to OPV, are gaining traction. Hybrid OPD-on-silicon detectors are especially promising, with the aim of increasing the sensitivity of silicon photodetectors to the short-wave infra-red (SWIR) spectral region. The technological/commercial readiness level of the different organic semiconductors is given in the chart, along with other materials and applications with large or fast-growing markets.

An IDTechEx technological/commercial readiness level assessment for selected printed/flexible electronics materials and their applications. Source: IDTechEx “Materials for Printed/Flexible Electronics 2021-2031: Technologies, Applications and Market Forecasts”

For component attachment materials, opportunities abound due to the emerging manufacturing methodology of Flexible Hybrid Electronics (FHE), which combines printed functionality with placed components. This composite approach requires robust component attachment materials, capable of linking rigid components to flexible or even stretchable substrates with very different mechanical and thermal properties. As such, a range of innovative attachment materials are being developed and are gaining commercial traction. These include low temperature solders with reflow temperatures compatible with low-cost polymeric substrates, and field-aligned anisotropic conductive adhesives that enable components with closely spaced contacts to be mounted more rapidly.

Comprehensive analysis

The new IDTechEx report “Materials for Printed/Flexible Electronics 2021-2031: Technologies, Applications and Market Forecasts” provides a definitive assessment of this diverse and growing market. Our granular market forecasts (in both revenue and volume (kg)) cover each of the material categories outlined above, with breakdowns into further subcategories where relevant. The market is enabled by specialized, functional materials, with the report focusing on material requirements, progress, and opportunities. Technical analysis and an interview-led approach bring the reader unbiased outlooks, benchmarking studies, and player assessments across this diverse and expanding industry.

For more information on this report, please visit www.IDTechEx.com/PEMats or for the full portfolio of Printed and Flexible Electronics research available from IDTechEx please visit www.IDTechEx.com/Research/PE.

IDTechEx guides your strategic business decisions through its Research, Subscription and Consultancy products, helping you profit from emerging technologies. For more information, contact [email protected] or visit www.IDTechEx.com.