Barcode reading under difficult conditions

Aging handheld laser scanners are considered outdated technology: When the forklift drivers load trucks at the Flensburger brewery with filled kegs or beer crates, a Cognex barcode reader mounted on the mast recognizes the pallet label and scans the barcode. This not only saves time, but enhances safety in congested forklift and truck traffic, and has proven its worth since the technology was installed.

In beverage logistics, operations centers require large amounts of goods to be handled at high speed. This is particularly true for the Flensburger brewery, as the company has achieved growth in a virtually stagnant market and sold a record of 628,000 hectoliters of beer in 2018. In other words: 172,000 liters of beverages were brewed and bottled per day, and divided into 17 kinds. The bulk of the beer brewed continues to be the legendary Flensburger Pilsener with the distinctive swing top. The non-alcoholic beverage segment is also seeing strong growth, which has facilitated a business decision to build a new, larger logistics center.

The readers can read all codes without a problem, even in poor ambient light, as they are equipped with high-performance lighting accessories

A new code-reading solution for pallet identification

For the present, the logistics managers are working closely with Jetschke GmbH & Co. KG to optimize the flow of goods and information in the existing building. Jetschke is the licensed dealer for Linde forklift trucks in the far north. The company with over 270 employees provides and services the fleet of robust and high-performance multi-pallet forklift trucks that convey the “Flens” to the trucks. In addition, Jetschke is responsible for incorporating mobile scanning solutions into the information flow, i.e. into Flensburger brewery’s merchandise management system.

Historically, the forklift drivers were equipped with a handheld scanner, with which they recorded the pallets to be loaded. A terminal in the forklift truck cabin displayed which lorry was to be loaded with the respective pallet and once the pallet was scanned and put on the lorry, the system registered the item as “loaded.” This is a common practice in many companies.

In beverage logistics, the technical equipment must withstand a lot. Thanks to their robust design, the DataMan readers from Cognex consistently achieve extremely high read rates over time

However, Jetschke’s experts aimed for an even faster solution that was comfortable for the operators. The idea: An image processing system is mounted on the forklift truck’s mast, which automatically recognizes the palette’s EAN code. The driver simply activates the scan at the touch of a button, and is otherwise able to fully concentrate on driving and lifting the pallets; eliminating the need to handle the scanner. This saves time and enhances safety with the high volume of forklift trucks and trucks in the goods issue area.

Wanted: Robust identification technology

While the idea of installing fixed mount barcode readers to the forklift truck masts seems good in concept: It can only be carried out if the barcode reader is robust enough to be able to withstand the constant vibrations and impact loads that act on the mast during the journey. The tough environmental requirements disqualified some common types of devices, such as laser scanners. They contain moving parts that would not survive long under the arduous conditions of beverage logistics.

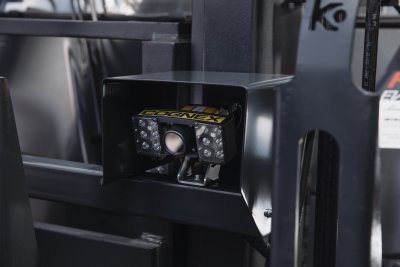

Fortunately, the logistics operations team evaluated Cognex DataMan 360 Series image-based barcode readers. They are ideally suited for robust industrial barcode reading applications — as they have no moving parts and are designed from the ground up to withstand tough environments.

The splash guard protects the readers from everyday damage

Image-based barcode readers prove themselves

Christian Ludwig, a Business Solutions specialist at Jetschke, chose to use the DataMan 360: “Because the software is already integrated into the reader, the devices are robust, easy to install, and are easy to adapt to the individual requirements of the application. The large depth of focus of the optics and the very high read rates, even under unfavorable conditions, are also advantageous.” The labels with the codes on them are often creased or partially torn due to the harsh environmental conditions. Nonetheless, the barcode readers at Flensburger brewery achieve continuously high read rates thanks to Cognex’s robust decoding algorithms.

Even creased, torn or reflective codes can be read with the image processing-based devices’ robust decoding algorithms

Flensburger brewery uses additional numeric coding on their pallet markings next to the barcode, so minor adjustments were required and were quickly completed. Christian Ludwig: “We also equipped the readers with a splash guard as they are used outdoors.”

The forklift drivers no longer need to read the codes with handheld scanners, but only need to push a button to trigger the scanning process. This new solution brought huge time and cost savings, both through the modified scanning process, as well as eliminating the additional expenses associated with fixing damaged, unread codes. The masts of six Linde forklift trucks in the logistics center have been fitted with Cognex’s DataMan readers and the solution is proving a success.

Piotr Kaczmarek and Christian Ludwig, Business Solutions specialists at Jetschke, used their great knowledge and skills to meet the challenge