Tacho generators in drives of mountain railways and ski lifts are exposed to enormous strain. Nevertheless, they must perform for precise and reliable speed measurement. This is why manufacturers rely on HeavyDuty solutions from Baumer Hübner. What does it take for a tacho generator to withstand the rough conditions on snow-covered mountains?

Every day and for many years, the cable railway traveling in the Tyrolean Alps to the top of Zugspitze has been carrying hundreds of people to an altitude of 2,964 metres. At a speed of 10 metres per second, the trip takes about seven and a half minutes, powered by two electric motors of 500 kW. In the driver’s cab, control of the current motor status – slow, idle, forward, reverse, accelerate, high-speed and brake – requires a high level of accuracy and reliability by the speed control system. After all, passenger comfort and safety are first.However, the components in mountain railways are exposed to harsh conditions: Wind, rain and snow shape the ambience, temperatures range from double-digit minus degrees in winter to high plus degrees in summer. A perfect application example for the HeavyDuty tacho generators from Baumer Hübner, here analog tachor generator TDP 0.2 LT which is a particularly robust and precise speed sensor variant. What exactly does “HeavyDuty” mean?

HeavyDuty as encompassing performance promise

“HeavyDuty means “heavy-duty”. To Baumer Hübner, however, this is much more than thick-walled housings and corrosion protection. HeavyDuty is the encompassing promise of never letting users down thanks to reliable performance for many years. A prerequisite particularly in mountain railway applications. To ensure this, some specific criteria must be met:

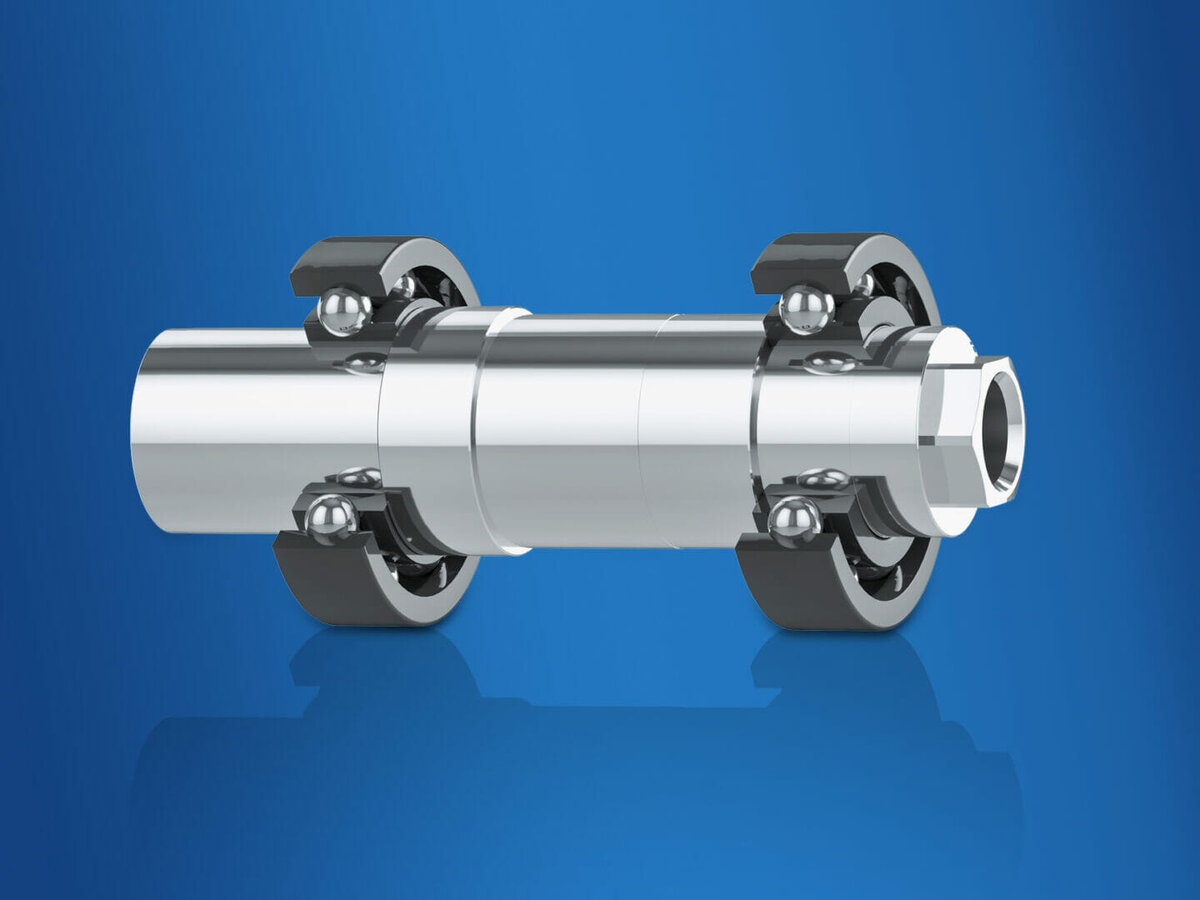

Mechanical robustness of course is key. Tacho generators in mountain railway drives must withstand shocks, vibration and other impacts the rotating shaft is exposed to for many years, without losing any of their functionalities. After all, product exchange is expensive, not because of tacho pricing but because of installation in places difficult to access and system downtime during exchange. Robust housings with solid walls are a good start, so TDP 0.2 LT comes in a die-cast aluminium housing and with stainless steel shaft. But also the interior must be protected against shocks and vibration. TDP 0.2 LT with bearings at both shaft ends is capable of enduring high radial and axial shaft load.

HeavyDuty tacho generators must withstand dust, dirt and moisture which requires a sufficient level of tightness. For this reason, the HeavyDuty housing is well sealed, especially at critical, neuralgic points – shaft and electrical connections. In addition, appropriate materials and coatings protect against corrosion by salt water or chemicals.

Tacho generators do not integrate electronics and therefore are extremely durable against harmful impacts by electromagnetic fields. So, nothing stands in the way for routing live, unshielded cables nearby. Furthermore, shaft currents induced by voltage differences might burn the bearing lubrication which results into bearing destruction. The electrically insulated interior of HeavyDuty tacho generators is therefore well protected against such harmful influences.

Last but not least, precision is another valuable virtue of these HeavyDuty heavy weights. Tacho generators must deliver reliable signals at all times to ensure precise drive control and regulation. Based on the speed information, the controller can identify any drive speed deviation and will intervene. HeavyDuty tacho generators in heavy vehicles such as mountain railways must be as precise as smaller speed sensors. It is not without reason that TDP 0.2 LT is field-tested and extremely reliable. It delivers a 60V output signal already at 1000 rpm; at the maximum operating speed of 10,000 rpm the controller is even provided with up to 600V.

High-precision tachometer voltage throughout the entire speed range

The conventional combination of copper commutator and graphite brushes in tacho generators has long been outdated. The copper oxide layers on the commutator cause irregular transition resistance and thus high ripple in tachometer voltage, so low speed would not be accurately detected. However, graphite with good sliding properties ensures a long brush service life. The combination of copper commutator and silver graphite brushes is much more appropriate for low speed detection, since precious metal brushes apply a highly conductive “patina” to the commutator. However, this solution is sensitive to adverse ambient conditions such as oil, grease or air containing sulphur and salt. Under such conditions no patina would build up and the said good transmission properties would be lost over the entire speed range. In addition, there is increased wear because the metal-containing brushes run directly on the copper layer.

LongLife® is what Baumer Hübner calls their tachometer technology patented in 1987 which combines the positive of above procedures and eliminates the drawbacks. In a special process and depending on the tacho variant, Baumer Hübner embeds one or two massive silver tracks into the commutator surface. The track can be very fine thanks to relatively minor tacho currents. TDP 0.2 LT features even two silver tracks. This ensures permanent low contact resistance even under difficult conditions. And it allows for a 60 mV/min-1 voltage constant of TDP 0.2 LT resulting in a wide detectable speed range from ≤ 0.08 to 10,000 min-1, with both mechanically and electrically limited maximum speed. TDP 0.2 LT therefore provides a dynamic range of 1 : 125,000. The brushes especially modified by Baumer Hübner together, with the LongLife commutator ensure maintenance-free service life that even will exceed that of the ball bearings.

LongLife® even for ski lifts

Ski lifts carrying millions of skiers to mountain peaks every year have likewise tough requirements on drive control. Here too, to ensure passenger safety manufacturers rely on tacho generators that have proven themselves in many applications. They ensure reliable equipment functionality even during severe frost, snowfall and icy winds. Today, speed-controlled drives are also common in ski lifts for smooth starts and variable travel speed. For decades, lift manufacturers have been deploying analog tacho generators by Baumer Hübner such as GMP 1.0. The tacho generator is directly connected to the slowly rotating cable wheel via step-up converter and chain wheel drive. This way, dead speed in the motor gearbox is isolated from the control loop and generates sufficient speed signals even under harsh ambient conditions. The GMP 1.0 also features two silver tracks for permanent low contact resistance and thus a widely detectable speed range with good transmission quality of measured values. The robust design and standard temperature compensation make the tacho generator ideal for use in the harsh conditions of snow-covered mountains.

More than half a century of experience in HeavyDuty tacho generators and encoders has evolved the comprehensive Baumer Hübner portfolio of reliable, precise and durable product variants – from small to large designs. They support all relevant analog and digital interfaces and excel with the capabilities required to withstand even adverse ambient conditions. Application examples like mountain railways and ski lifts clearly prove that for users with high requirements the HeavyDuty Original is the right choice in this encoder class.