Aluminium is the second most widely used metal globally thanks to its versatility, which makes this material popular among various industries. In particular, the metal is recyclable, lightweight, durable, resistant to corrosion, ductile and malleable. By leveraging die casting manufacturing processes, industries can further maximise the benefits of using aluminium and gain a considerable competitive advantage.

Pierluigi Buffagnotti, Production Manager at Aluminium Die Casting, looks at the strengths and challenges in making the most of aluminium die casting.

Cold chamber die casting is a fast and economical manufacturing process for the high-volume production of metal parts. This process liquifies aluminium – or any of its alloys – into furnaces, transfers it into a cold chamber and subsequently injects the metal into designated moulds or dies. These are designed and created with exact specifications in order to obtain products that can fulfil the specific application by means of defined shapes and attributes.

Unlimited design possibilities for metal parts

The greatest capability offered by aluminium die casting processes is their ability to create parts of any shape in a highly accurate manner by means of suitable moulds. More precisely, industries can benefit from fully customisable mould designs that deliver products with negligible dimensional variations.

The design possibilities are limitless as aluminium die casting can produce parts with weights ranging from a few grams up to tens of kilograms. In addition, this technique supports complex shapes that combine multiple functions in one uniform object.

Nonetheless, particular attention should be given to any angles within the mould. More precisely, draft angles should be carefully designed and undercuts should be avoided, as they can hinder the removal of the end product from the mould.

In order to address this issue, Aluminium Die Casting, a brand of Altra Industrial Motion Corp., offers advanced insights into what constitutes the optimal design for die castings. Experts check the product design provided by the customer and develop a suitable mould design. If necessary, variations in product design are suggested to facilitate the extraction of the product.

Deliver consistently high-quality castings

Another key aspect that Aluminium Die Casting takes into account to deliver high-quality metal parts is the presence of air during the injection of aluminium. This is a common issue in die casting, as it causes defects and inhomogeneities within the object’s microstructure. Therefore, the company regularly performs advanced computational fluid dynamics (CFD) simulations, porosity analysis and thermal imaging during the mould design phase to minimise the likelihood of trapped air and ensure homogeneous castings. In addition, vacuum systems are in place during the casting process to remove any remaining air, giving Aluminium Die Casting’s customers a further assurance about the quality of its products and solutions.

More than casting

Aluminium die casting also opens up new possibilities in terms of product wall thickness, which can reach extremely low values. For example, Aluminium Die Casting can produce metal parts with thicknesses as low as 2 mm with its current equipment. As a result, it is possible to build lightweight metal structures.

This aspect is particularly advantageous for the automotive, transport and aerospace industries, which can improve the fuel economy of their vehicles by replacing heavy steel structures with lighter yet equally strong aluminium counterparts.

The ability to fine-tune dimensions on such a scale also means that die cast surfaces tend to be smoother than most other casting production methods, offering near net shaped engineered parts. While many metal components are used “as cast”, there may be special applications that require particular mechanical or surface properties. In these cases, heat treatments or surface finishes can be included.

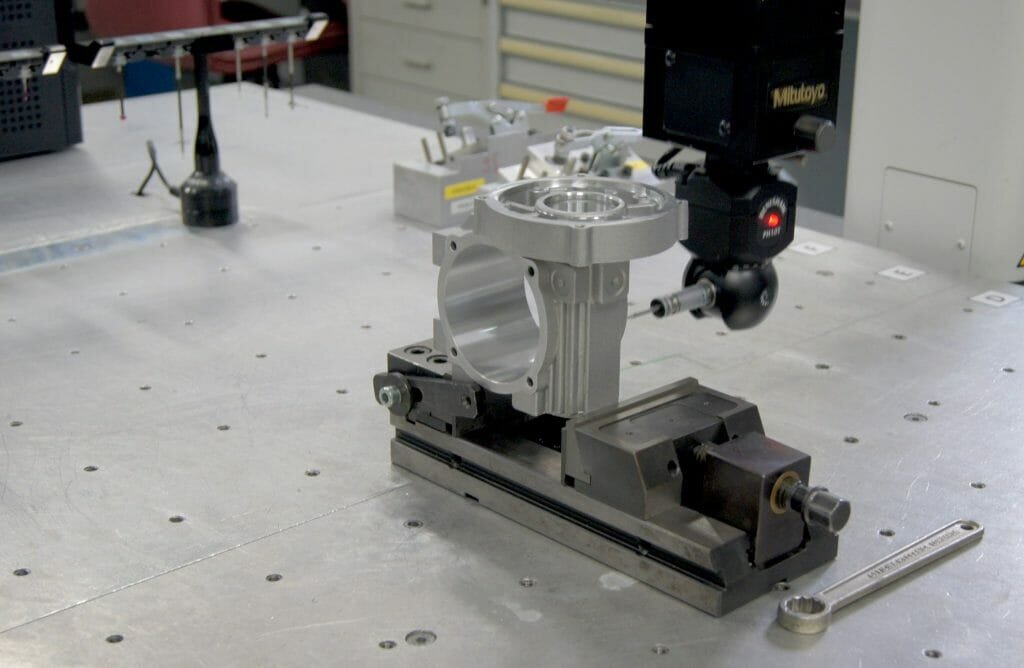

In order to provide its customers with a single point of contact, Aluminium Die Casting offers a broad range of services that complement the die casting offering. More precisely, the company offers heat and surface treatments, such as painting, varnishing and impregnation, as well as CNC machining that can further optimise the quality and performance of end products. For example, in addition to its 10 high-pressure die casting machines, Aluminium Die Casting boasts a total of 19 computer numerical control (CNC) machines.

Thus, the company not only provides an aluminium die cast raw part but a completely finished high-quality and reliable product to its customers.

At the forefront of innovation

Die casting is per se an efficient, fast, reliable and reproducible method for the “just-in-time” production of high-quality metal components. The latest advances in industrial automation, process control and robotics can further maximise the capabilities of this production method, as they provide greater actionable insight into the manufacturing processes.

Aluminium Die Casting is committed to total quality management practices to deliver complete solutions that comply with environmental regulations as well as energy-efficient production processes. According to its strict quality control and quality assurance systems, the company performs in-line and off-line product testing within its in-house facilities.

In addition, each die casting machine is equipped with robotic arms that make it fully automated and independent. Similarly, robots are responsible for loading components on several of Aluminium Die Casting’s CNC systems.

Such an automated factory floor not only improves product quality and reproducibility, but also results in shorter production times that can substantially help customers to receive their metal parts quicker and in a more economical manner.

Thanks to these cutting-edge solutions and its extensive expertise, Aluminium Die Casting offers futureproof technologies for the production of metal parts.