Force Engineering, based in Shepshed near Loughborough, develops and manufactures customised Linear Induction Motor (LIM) based motion systems, serving a wide base of industries with applications as diverse as medical scanning equipment and baggage handling conveyors. As a world leading expert and innovator in the field of LIM technology, a large part of Force Engineering’s activities centres on the amusement ride industry – adding heightened levels for thrill-seekers through ride launch and in-ride acceleration to 1.2 g, and equally rapid braking performance along roller coaster tracks. To help ensure the extreme levels of electrical safety and performance required for these high power systems which typical run from very high current three-phase supplies, Force Engineering embed temperature controls in its LIM winding assemblies and has chosen Variohm EuroSensor as its main supplier of customised wiring harnesses that include glass encapsulated NTC thermistors configured as temperature probe assemblies.

The special temperature probes are similar to standard components available as stock items from Variohm EuroSensor, however with 10K3976 series thermistors which offer a higher temperature range and stability specification than the standard probe. With the NTC chip encapsulated in hermetically sealed glass packages, these thermistors – which are supplied to Variohm from TE Connectivity, the global sensor and measurement systems company – are in turn encapsulated and fully sealed in copper tube housings by Variohm EuroSensor at its Towcester manufacturing facility.

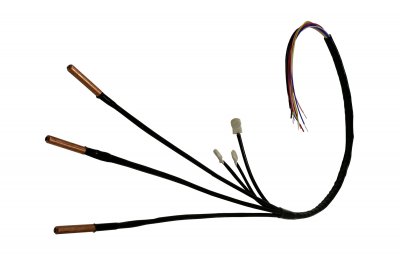

Image: Variohm’s customised wiring harness with NTC sensors encapsulated in a tubular copper housing

The 10K3976 glass thermistor has a temperature range of -40 to +250 ⁰C and is specified in applications where a fast time response is required at high levels of thermal shock. Three special probes are each wired with different length leadwires and coloured insulated, all finished with rubber shrink-sleeving. Additional cabling, without thermistors, is also included in the harness to facilitate straightforward assembly into the LIM’s manufactured by Force Engineering.

In addition to specialist temperature probe assemblies, Variohm also includes customised production by transforming other components from its wide range of sensors for linear and rotary position, pressure, load/force, and vibration etc. Modifications can range from alternative electrical connection or a modified mounting arrangement to integrating sensors with significant redesigns or combining multiple sensor technologies and other electromechanical components as fully tested sub-assemblies.