Pumps are critical to food manufacturers and processors, whether for adding specific quantities of ingredients into ice creams or yogurts, handling delicate items such as soft fruits, macerating poultry by-products or anything in between. There are a number of different pump types on the market and choosing the right one for your food production process can seem like a daunting task. However, in today’s squeezed economy, maximising productivity is essential if food companies are to remain competitive – and correct pump selection is key to this.

What is productivity?

Productivity is measured by the ratio of output per unit of input. Many food companies see it as a balancing act – how can they increase their output without increasing their costs? It is closely linked to efficiency, ensuring that every piece of equipment and every part of the process is optimised, delivering greater value for money to the operator.

Knowledge is power

The most important criteria when specifying a pump is to ensure that it will be fit for purpose. To do this, it is important to understand the product to be pumped, and the process involved. Is the product in question liquid or semi-solid? Is it viscous? Will it need to be transferred over a long distance, or pumped to height, for example to storage vessels?

Other information must be provided for correct pump selection, too. For example, does the product contain solid particles? Consider also whether it is shear sensitive, if the process needs a self-priming pump, or whether a suction lift is needed. For hygienic applications the cleaning regime also needs to be considered, such as whether cleaning in place (CIP) or manual cleaning will be used. Also bear in mind the length of the discharge pipework and the configuration regarding bends and lifts. The more information an operator can provide, the more likely they are to get the right pump for the job.

Before specifying a pump, it’s crucial to understand the product to be treated

Avoiding a false economy

After thoroughly researching the options available, it may transpire that more than one pump design is fit for purpose. While a number of pumps may be able to do the job, in order to ensure optimum productivity, operators must then consider the total cost of ownership (TCO). Although some food manufacturers and processors can be swayed by the initial purchase price, this can be a false economy. The lifecycle cost of a progressive cavity (PC) pump, for example, is typically ten per cent capital purchase cost, ten per cent maintenance/spare parts, and eighty per cent energy costs (based on £0.10p per kW/hr over a 20-year period, using WIMES calculations). To keep productivity high, it is therefore essential to consider the TCO of a pump, not just the purchase price.

Energy efficiency

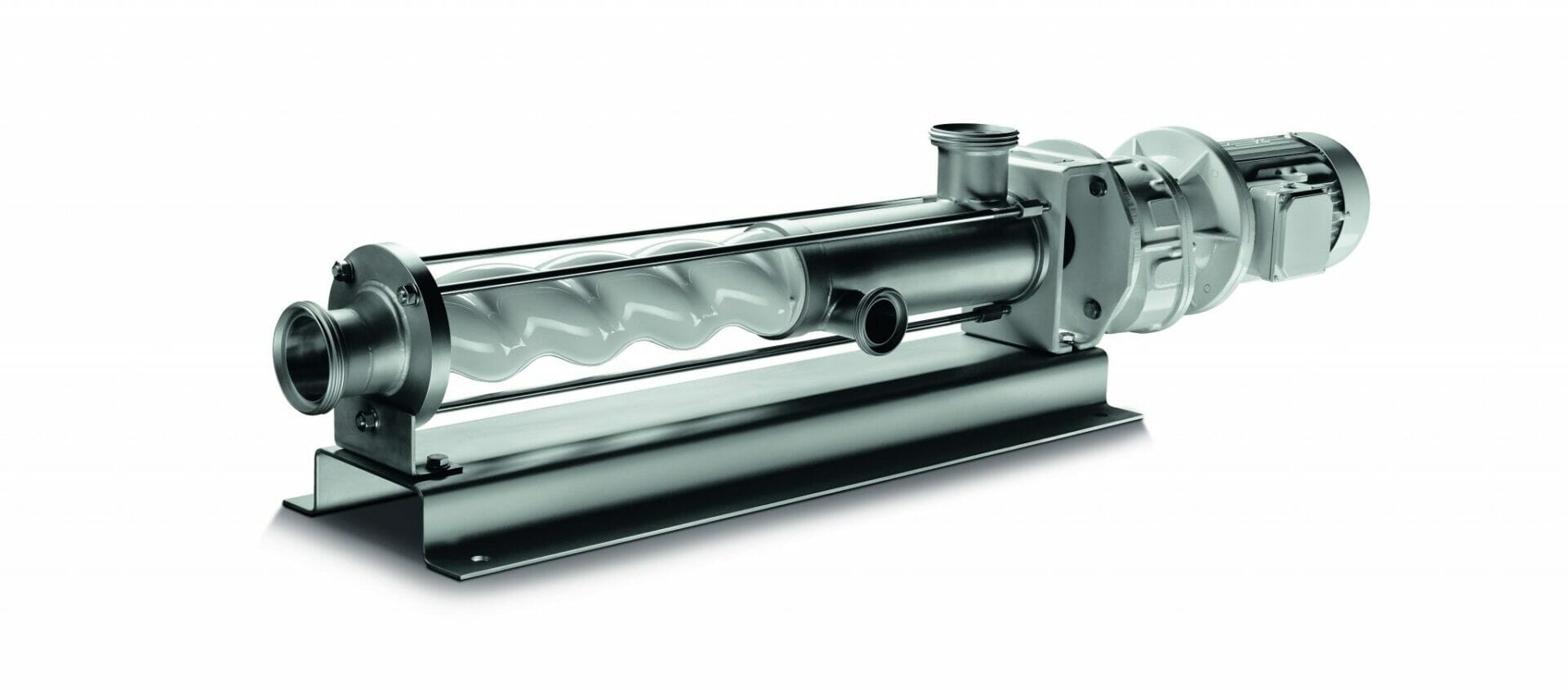

With such a high percentage of a pump’s TCO coming from its running costs, selecting a pump which is energy efficient is key to enhancing productivity. Unlike piston, diaphragm and peristaltic pumps, PC pumps produce low pulsation flow and require smaller drives and motors for the same duty. And unlike air-operated pumps, they run on a direct energy source, without the conversion of electricity to compressed air. This all helps to reduce the energy required to run the pump. Some of the more intelligent pumping solutions on the market, such as SEEPEX’s Smart Conveying Technology (SCT), deliver even greater energy savings. By optimising the clamp between the rotor and stator, and using a variable speed drive, the SCT pump can be up to 20 per cent more energy efficient than traditional PC pump designs.

SEEPEX Hygienic design PC pumps for shear sensitive products with or without soft solids

Maintenance matters

As maintenance and spare parts are responsible for 10 per cent of the TCO of a pump, finding a solution that is easy to monitor and maintain is also important. SEEPEX’s SCT range of progressive cavity pumps significantly improves whole life costs due the ease of replacing parts and clearing blockages. The fact that these pumps can be remotely monitored also makes it easier to anticipate problems, enabling predictive maintenance. In addition, the use of variable frequency drives (VFD) means that speed can also be controlled. This is important because as the pump performance drops over time, its speed will increase to maintain flow; once this is identified, the SCT pump can be very quickly adjusted to regain its original capacity, keeping efficiency high and providing more time to plan for maintenance, resulting in less downtime for operators. The use of level controls with VFD to speed and slow pumps, and the regular, laminar flow created also helps to deliver a higher quality, more uniform pumped product. This reduces the wear rate of the pump, extending its service life.

Beware hidden system costs

Another cost consideration for food processors is whether a pump will require the purchasing of ancillary equipment. Many traditional pump designs such as piston, diaphragm or other positive displacement pumps require pulsation dampeners and check valves, all of which come at a cost to the operator, as well as being liable to blockages as solid particles can get caught behind the valves. In contrast, due to their constant, virtually pulse-free action PC pumps do not require dampeners, and the interference fit between rotor and stator negates the need for check valves, saving operators money and reducing downtime.

In addition, high-pulsation pumps increase the pressure rating of the downstream pipework; the higher the pressure generated, the greater the cost in terms of pipework and associated valves. PC pumps have a low pulsation action which generates a lower pressure on discharge, reducing costs of pipework and valves – when pumping viscous material, for example, a PC pump reduces the operating pressure generated to one third of that generated by piston pumps.

Lesley Eaton, Business Development and Marketing Manager for SEEPEX

Reducing purchase price

As well as keeping down the running, maintenance and system costs of a pump, food processors can also reduce their initial purchase price by talking to their supplier about the different options available. For example, could a smaller, smarter pump do the same job as a larger, more expensive solution? Is it worth integrating a boundary layer injection system to reduce pipework friction losses further downstream? Could labour costs be cut by specifying a pump with excellent suction lift capabilities, such as a PC pump which can lift liquids from the base of settlement tanks? Could operators reduce the need for a conveyor by selecting a PC pump over the alternatives, as they can easily pump over long distances? A responsible pump supplier will be able to work with a food processor to specify the most cost effective solution for their needs.

A balancing act

While a low pump purchase price may appear attractive, with 80 per cent of the TCO coming from its running costs, keeping these lower over the lifetime of the pump will provide a greater return on investment in the long run. Whatever solution you choose, make sure to take into account its energy efficiency, maintenance requirements and the costs of any ancillary equipment before signing on the dotted line. Put simply, specifying the wrong pump could decrease your productivity – choosing the right pump will almost certainly increase it.